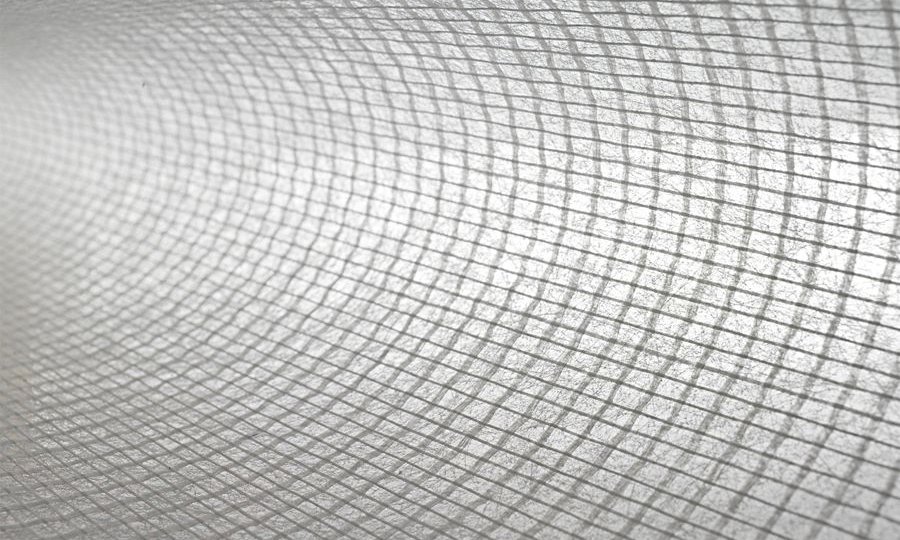

Multiaxial non-crimp fabrics

Compared to woven fabrics, the fibers in multiaxial non-crimp fabrics are not woven but laid parallel to each other and stitched together. This special alignment enables the fibers to absorb loads without undulations.

By combining different fiber materials, it is possible to create high-performance hybrid NCFs that combine the specific properties of the materials used in a single product.

Multiaxial non-crimp fabrics can also be combined with fleece materials or stitchbonded mats to create further properties during component production or in the finished structure.

Properties of multiaxial NCFs:

- Customizable fiber types and alignment options

Due to the different combinations of fiber materials and their alignment options, multiaxial NCFs can be perfectly designed and produced for the intended area of application.

- Drapability and permeability

Multiaxial NCFs from Vitrulan are produced in close cooperation with the customer and tailored to meet specific requirements. This makes them the perfect candidate for different types of processing such as RTM, injection or infusion processes.

- Resin compatibility

Since the choice of resin system determines the fiber type or sizing to be used, multiaxial NCFs are compatible with many different resin systems.

- Cost savings

Thanks to the various alignment options and adjustable weight of the single layers, fewer layers are needed, thereby also reducing the time and effort required for installation.

Alignment options

| Unidirectional NCF | 0°, or 90° |

| Bidirectional NCF | 0°, 90° |

| Biaxial NCF | +/-45° |

| Triaxial NCF | 0°, +/-45° or 90°, +/-45° |

| Quadraxial NCF | 0°, +/-45°, 90° |

![Unidirectional NCF [Translate to English:] Unidirektional](/fileadmin/user_upload/produkte/technische-textilien/Unidirektional.jpg)

![Bidirectional NCF [Translate to English:] Bidirektional](/fileadmin/user_upload/produkte/technische-textilien/Bidirektional.jpg)

![Biaxial NCF [Translate to English:] Biaxial](/fileadmin/user_upload/produkte/technische-textilien/Biaxial.jpg)

![Triaxial NCF 0° [Translate to English:] Triaxial 0°](/fileadmin/user_upload/produkte/technische-textilien/Triaxial_0grad.jpg)

![Triaxial NCF 90° [Translate to English:] Triaxial 90°](/fileadmin/user_upload/produkte/technische-textilien/Triaxial_90grad.jpg)

![Quadraxial NCF [Translate to English:] Quadraxial](/fileadmin/user_upload/produkte/technische-textilien/quadraxial.jpg)

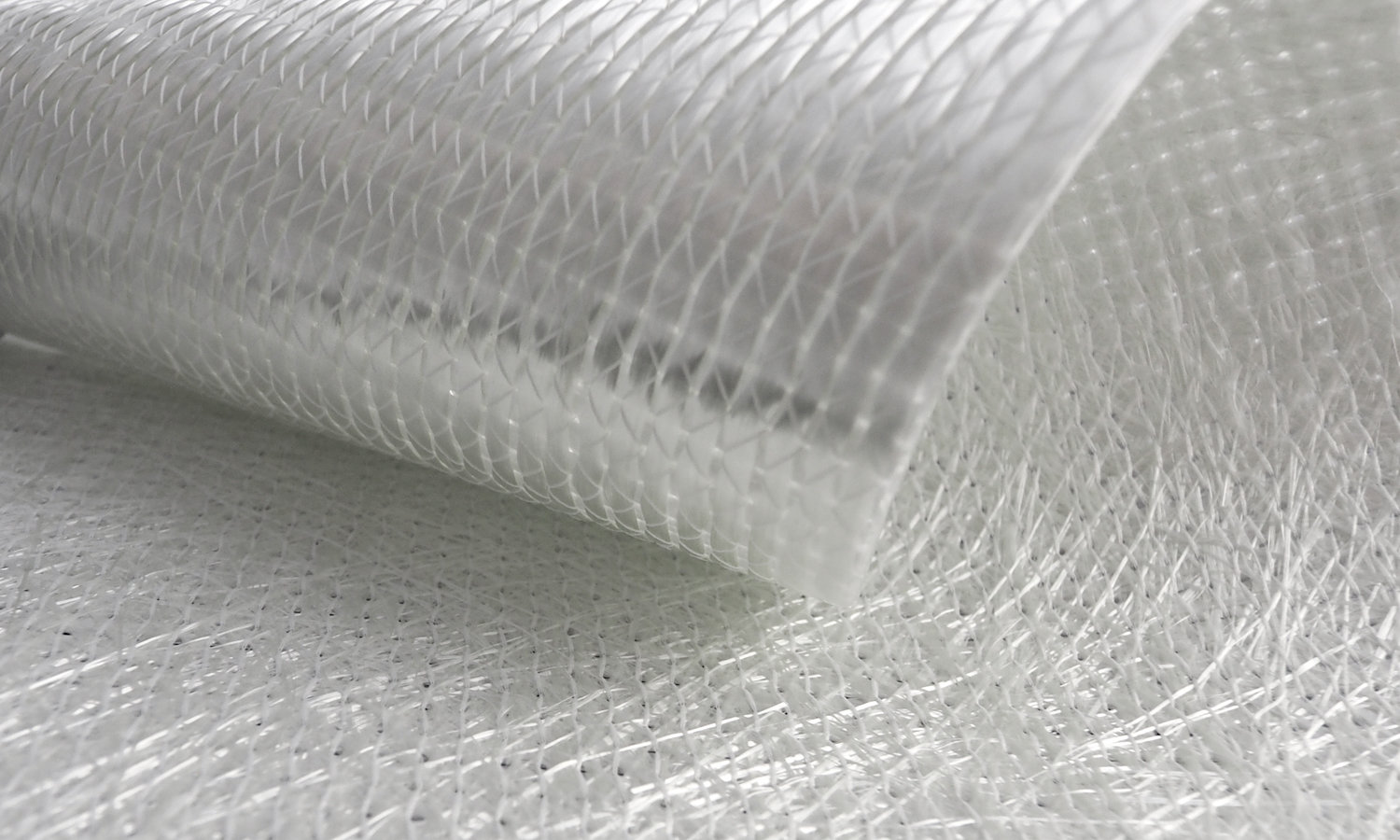

NCF/fleece combinations

NCF/fleece combinations consist of a multiaxial non-crimp fabric stitched together with a fleece.

Selection of the appropriate multiaxial NCF is based on the technical requirements of the relevant application. Constructions can be composed of unidirectional, biaxial, triaxial and quadriaxial NCFs. This enables the implementation of technical and mechanical high-performance solutions tailored to customers’ needs.

In addition, the fleece used in the combination enables the creation of a resin-rich layer that produces a good, even surface finish.

NCF/fleece combinations are used in the field of sport or automotive industry/e-mobility.

NCF/mat combinations

NCF/mat combinations can be manufactured in widths from 10 to 250 cm and are a combination of non-crimp fabric and chopped strand mat. To assemble a multiaxial NCF, the non-crimp fabric is stitched together with one or several layers of chopped strand mats, continuous filament mats or various fleece fabrics.

Selection of the appropriate multiaxial NCF is based on the technical requirements of the relevant application. Constructions can be composed of unidirectional, biaxial, triaxial and quadriaxial NCF. Customized solutions are also possible.

In addition to their technical and mechanical performance, NCF/mat combinations also help increase production efficiency.

NCF/mat combinations are used in shipbuilding, in the sports and leisure sector, in the transport sector and in sewer rehabilitation as well as in a range of industrial applications.

Custom reinforcement products

Are you looking for the right “reinforcement” for your product?

In collaboration with you, we develop a solution – tailored to the relevant production process and technical requirements of the finished product.

Simply use our contact form to describe your project. Our team is happy to help and will contact you immediately.